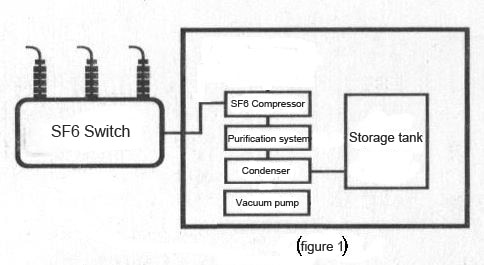

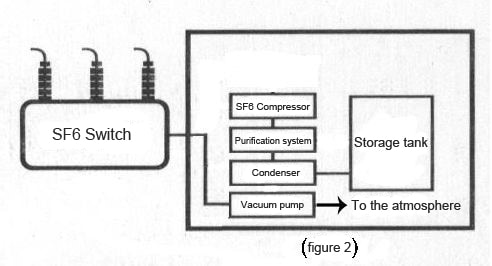

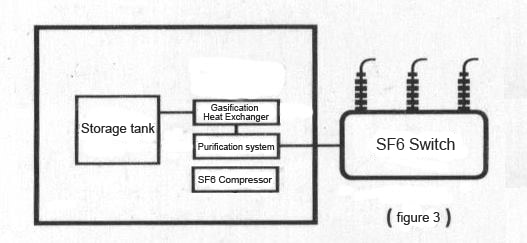

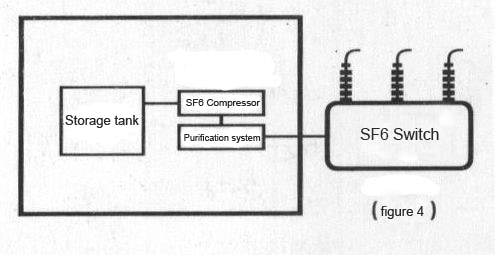

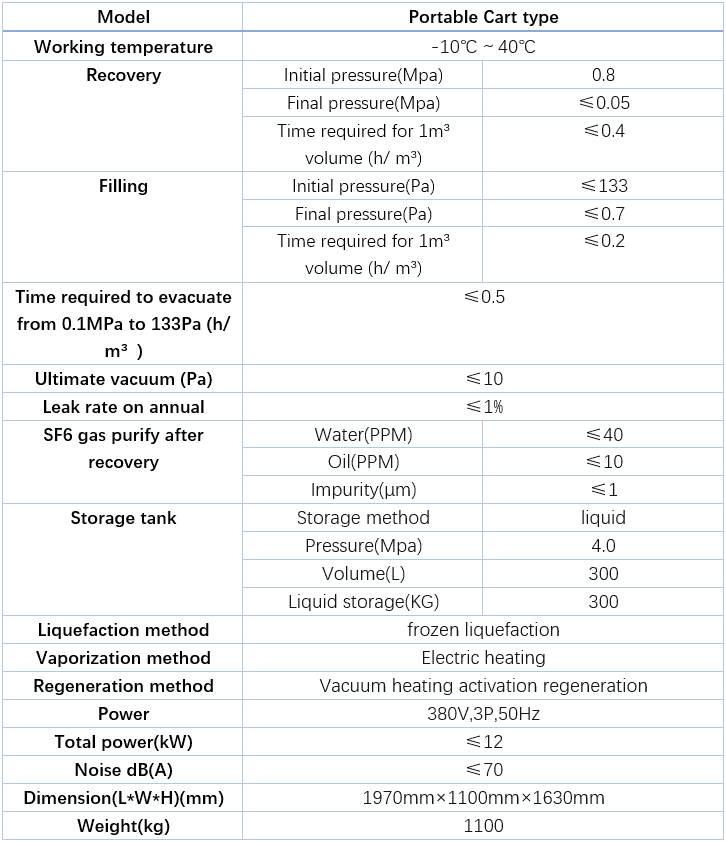

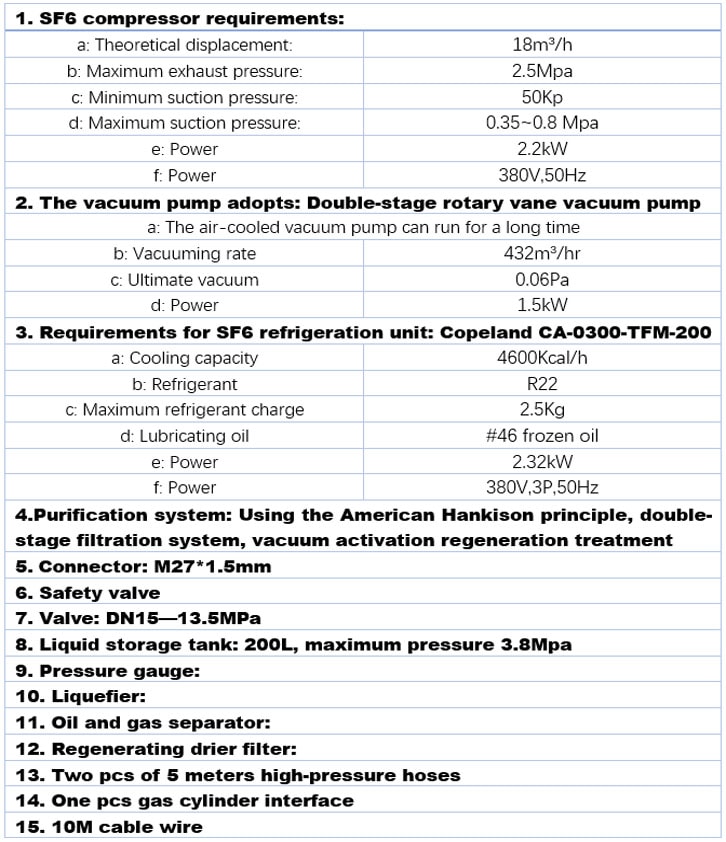

ASSEN SPF type SF6 Gas Recovery Device can be used to suck, liquefy and store SF6 gas from the insulating equipment.

SF6 Gas Recovery Device, Portable SF6 Gas Filling Plant, SF6 Gas Recycling Machine

ASSEN SPF type SF6 Gas Recovery Device can be used to suck, liquefy and store SF6 gas from the insulating equipment.