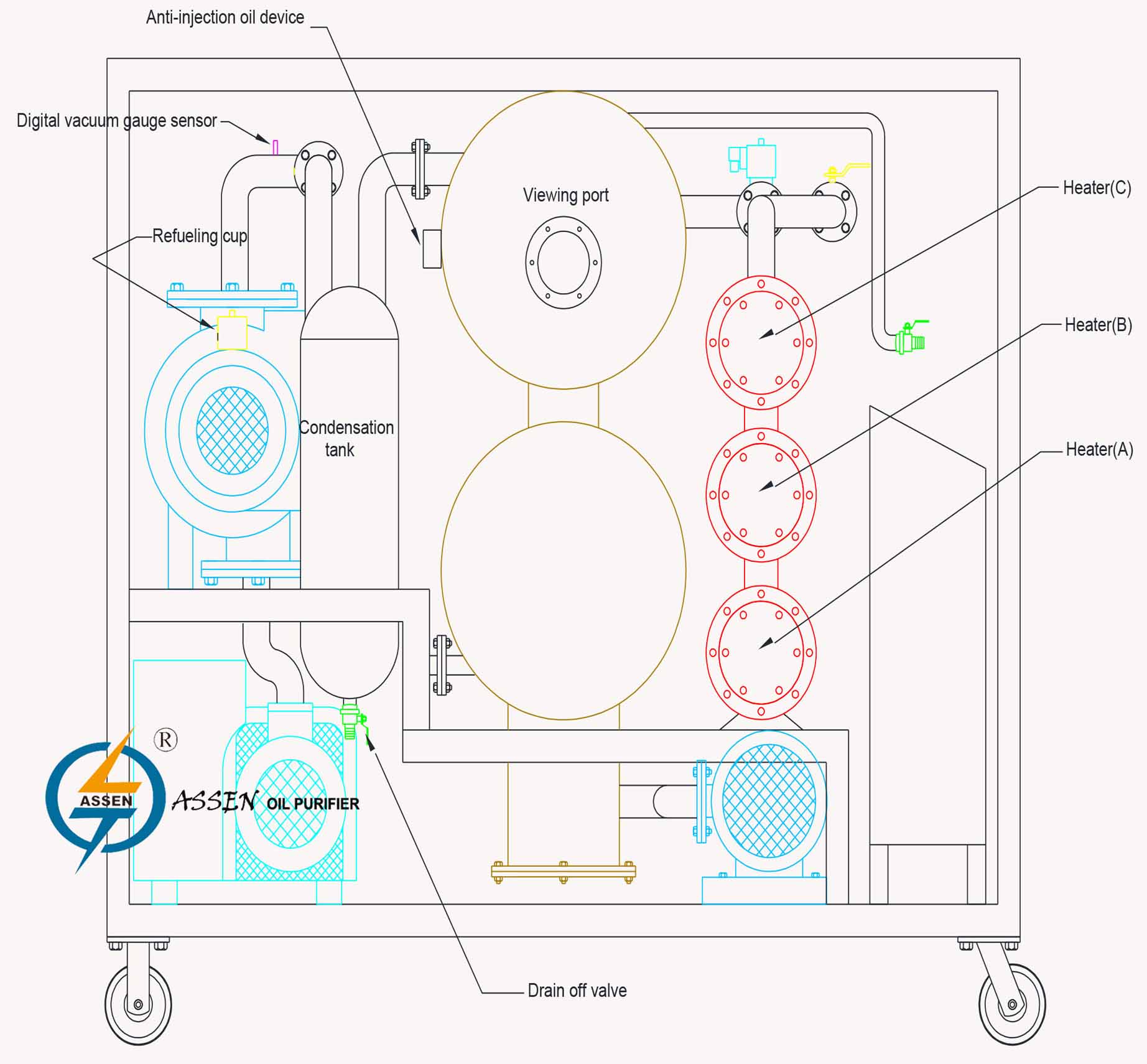

DVTP vacuum transformer oil purification plant equips Italy SEIM Screw oil pump, this gather benefits such as very low noise level, very low pulsation into the pumped medium, eliminate the production of acetylene gas, very perfect performance and long life.

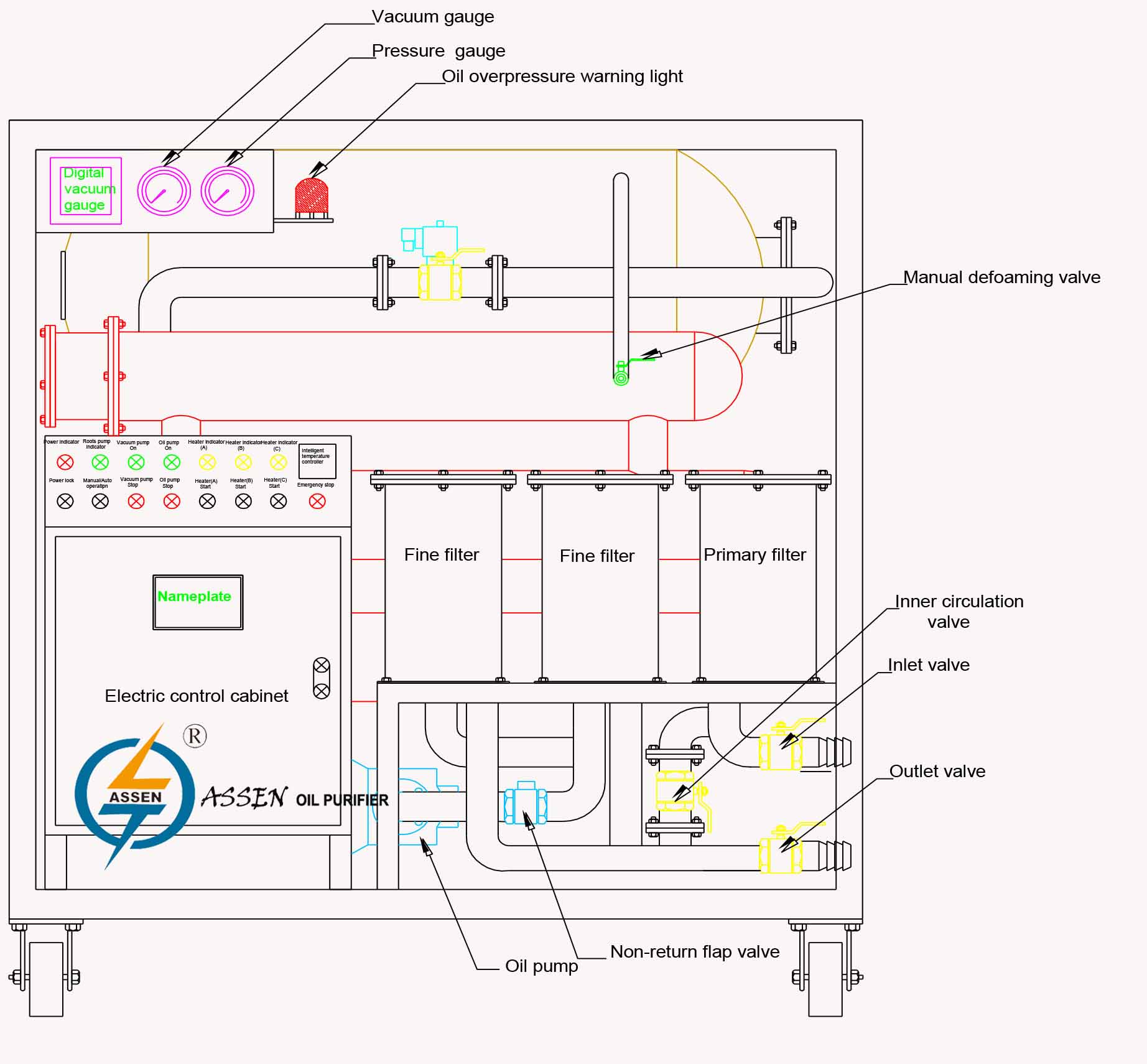

- With filter replacement indicator and filter saturation stop device

- It is equipped with leakage and overload stop devices to protect the motor.

- With phase sequence, phase loss protection function, sudden shutdown safety control system.

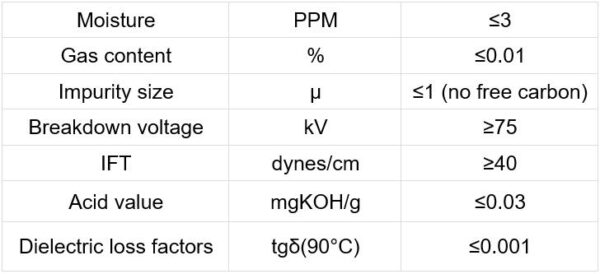

1). Expectations on an effective oil plant for treatment of insulating oil.

2). Suitable for oil treatment, vacuum oil injection and cyclic hot oil drying in the installation and maintenance of large capacity transformers.

3). Easy and failsafe operation.

4). On-line measuring and recording of process parameters.

5). Used in the electric power system (110kV~500KV).

6). Features include low noise, high-strength working vacuum, and high efficiency filtering process

7). Double-stage vacuum system, strong power of vacuum evacuating, ultimate vacuum value ≤5Pa

8). The unit can be used for the transformer vacuum oiling and for various wet electrical equipment vacuum drying.

9). Flexibility in application(flow frequency conversion, suitable for transformers of different sizes)

10). It is humanization design with low noise, deep purification and long time free maintenance to save cost from the running process.

We also have several plans for your choice;

a). Optional P.L.C. intelligent panel control, touch screen operation, and dynamic display according to user needs.

b). Optional Online PPM Meter, Optional flow meter with accumulator function.

c). Optional frequency converter, you can adjust the flow according to your needs

d). Optional external port design for transformer vacuum pumping

e). The whole structure can be made into mobile, fixed, fully enclosed, concealed, canvas, and open-type.

f). Optional three-stage high vacuum system for higher vacuum degree work.