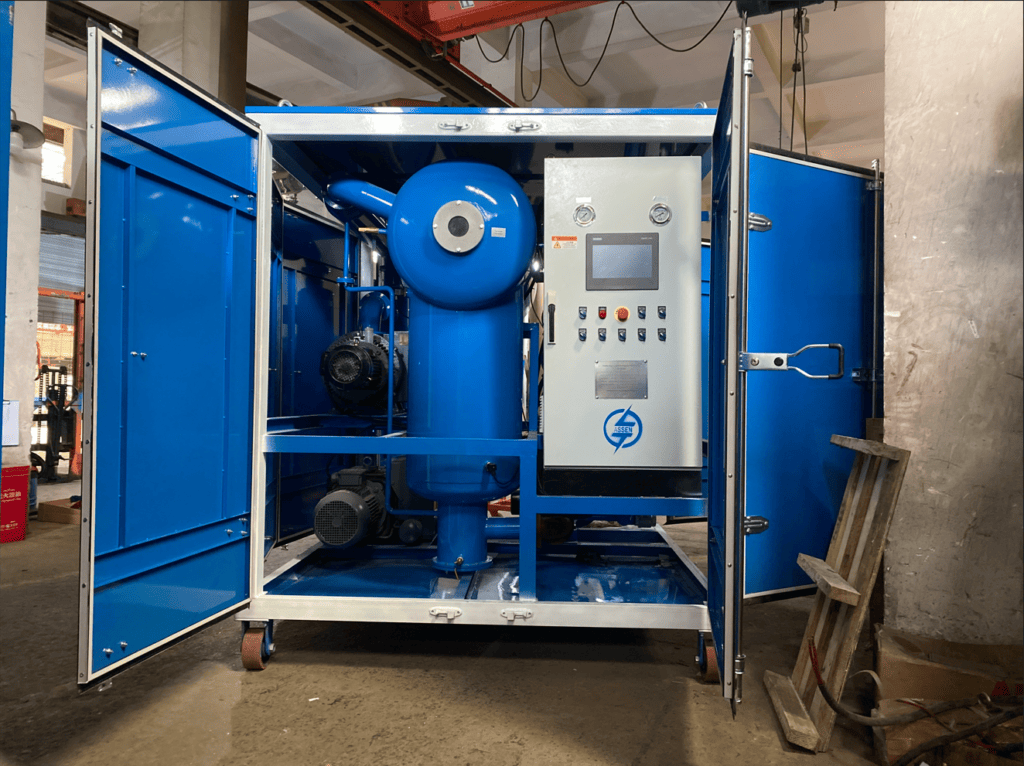

ASSEN DVTP Transformer Oil Dehydration machine keeps the transformer in good condition and increases its life. Not only use in Insulating oil purification treatment in 110KV-550KV transformer, but also applies to high-grade new oil, the high depth of processing imported oil.

Categories Oil Purification Machine, Transformer Oil Purifier

Tags oil purification plant, oil purifier, oil treatment machine, transformer oil dehydration, transformer oil dehydration plant, transformer oil filtration machine, transformer oil purification, transformer oil purifier, transformer oil recycling, transformer oil treatment

Additional information

| 1.PLC Mode | Optional P.L.C. intelligent panel control, touch screen operation and dynamic display according to user needs |

|---|---|

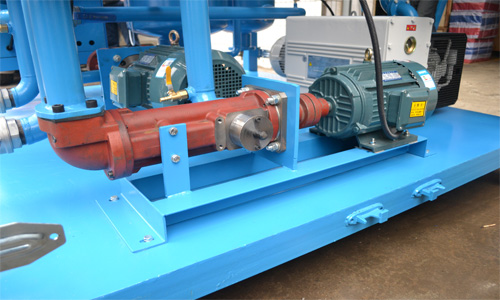

| 2.Flow Control Mode | Optional frequency converter, you can adjust the flow according to your needs |

| 3.Online Measuring Mode | Optional Online PPM Meter, Optional flow meter with accumulator function. |

| 4.Variable Mode | The whole structure can be made into mobile, fixed, fully enclosed, concealed, canvas, open type. |

| 5.Double Dehydrating Mode | Optional two high vacuum dehydrating chamber system for higher vacuum degree work |