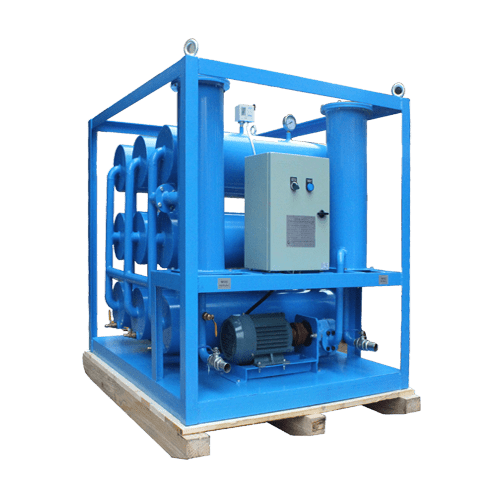

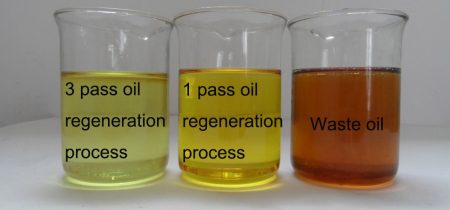

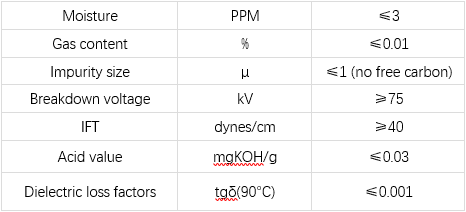

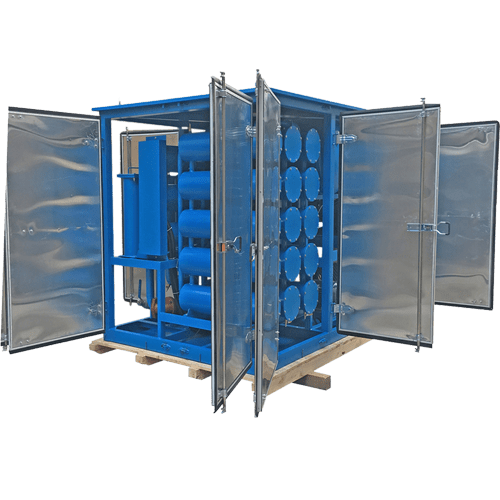

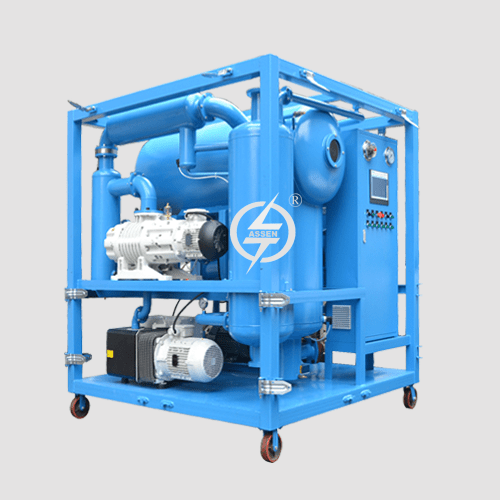

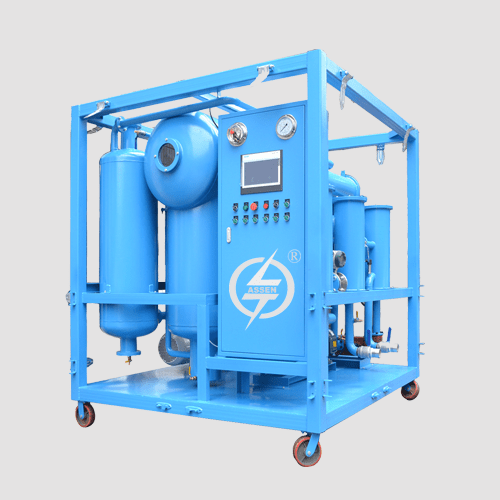

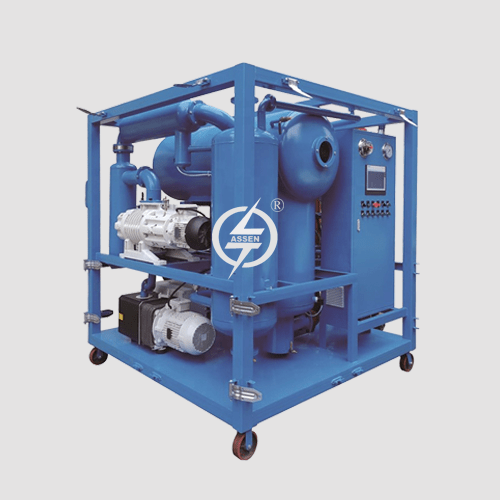

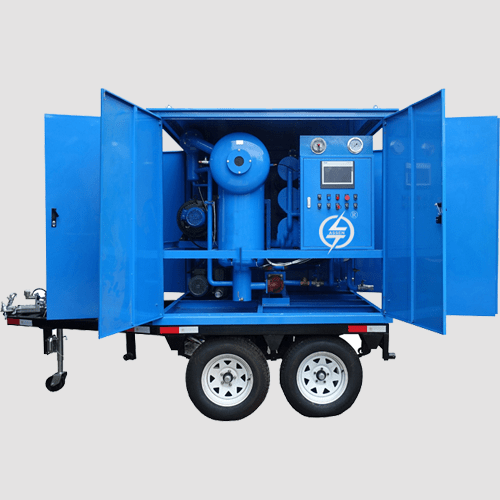

ASSEN DVTP-R Transformer Oil Regeneration system has been specially designed for on site use to completely regenerate insulating oils in de-energized transformers. Besides provides regular oil purification such as degassing, drying and particulate removal, it also can remove acidity, sludge, other soluble oil decay products and discoloration. After treating, the oil can be reused as new.

Categories Oil Purification Machine, Transformer Oil Regeneration System

Tags oil regeneration plant, oil regeneration process, oil regeneration system, power transformer oil regeneration, transformer oil reclamation, transformer oil reconditioning, transformer oil recycling, transformer oil regeneration, transformer oil regeneration machine, transformer oil regeneration plant