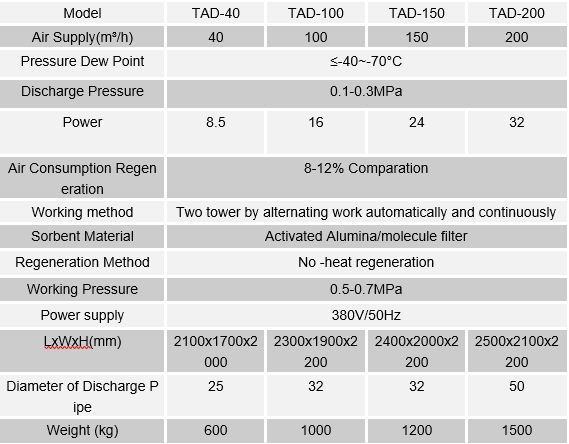

ASSEN TAD Dry Air Generator Plant is mainly regenerating dry air with low dew point when installing or repairing equipment such as transformers and reactors. The dry air it provides ensures that the internal insulation of the electrical equipment does not get wet, and the worker does not suffocate due to a lack of oxygen while working inside the equipment. Compare to using nitrogen, dry air is safer, more reliable, better economical, and convenient.

The dry air can ensure that the internal insulation of the power equipment will not be affected by moisture, and maintenance workers will not suffer from oxygen deficiency when working inside the equipment. It is safer, more reliable, economical, and convenient than using nitrogen.

With the help of a dry air generator, transformer overhaul can be performed day and night, regardless of the weather condition. The air drying system also shortens the maintenance schedule, improves the quality of inspection result

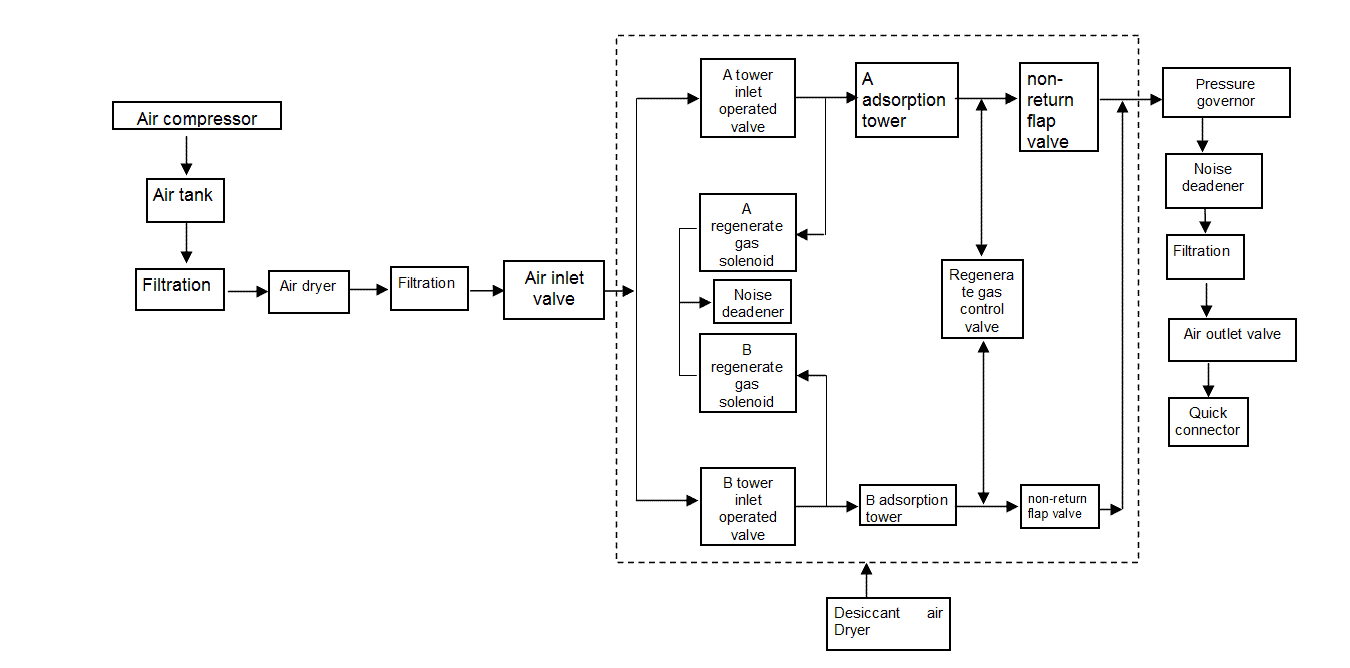

With advanced PLC control, the equipment can supply dry air at the site and is able to work continuously without manual assistance.